Manufacturing

Meet manufacturing targets with more streamlined inventory control, material requirements planning (MRP), and job shop floor control / manufacturing execution. Also, automate the quoting, ordering, and purchasing processes.

01. Meet customer Expectations

02. Track sales orders

03. Improve production planning

Our solution not only enables manufacturers to compete in the prevailing market atmosphere but also facilitates the transformation of the entire supply chain. By implementing our comprehensive suite, manufacturers can seamlessly integrate their production plan with their sales plan, manufacturing processes, financial operations, and customer interactions. Moreover, our solution empowers manufacturers to stay ahead of the competition by leveraging advanced technologies and streamlining their operations.

(MRP)Material Requirements planning

Material Requirements Planning Provides real-time visibility to combined sales order, inventory and procurement information. Detailed and well-planned material requirements for every manufacturing processes achieved to reduce material wastage. Helps to keep track of required stock and materials used.

Bills of Materials & Process Routings

Manage products that contain information that affects costing in BOM and process routing. Tracks items that must be produced in certain quantities to make parent/finished items. Track items in/out effective dates and quantity.

Manufacturing Order

Manage the transformation of manufacturing orders into final products. Define the information about the manufacturing order such as lead time, quantity, status and also define the number of resources, materials, work centers, run times and setup time and so on in the selected routings.

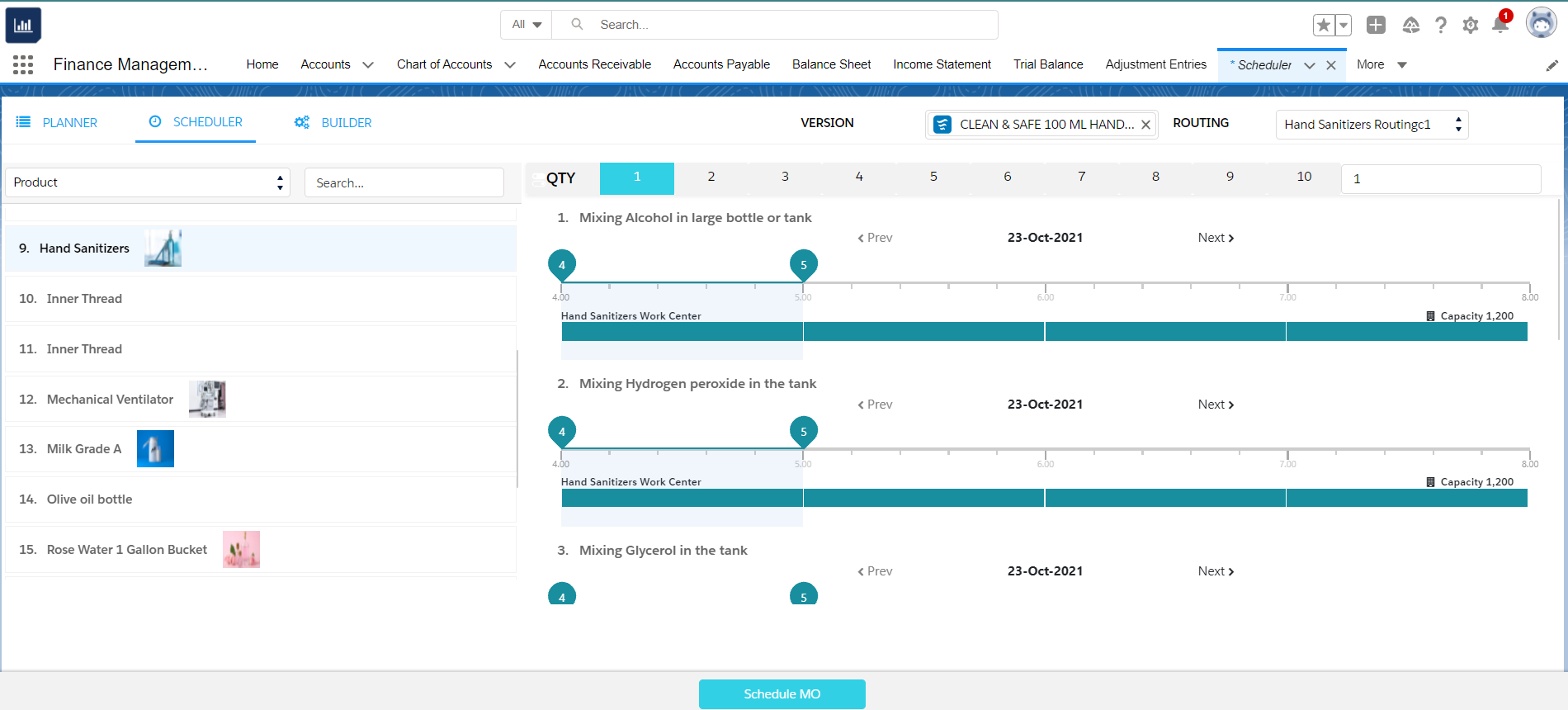

Scheduler

The Manufacturing Scheduler lets you view and reschedule single jobs and operations based on constraints, such as resource or material shortages. It provides you with a visual display of jobs on the shop floor. You can interactively reschedule jobs, operations, and resources. You can manually control the rescheduling or let the system automatically optimize the schedule based on resource and material constraints.